U of A finds new way to make sure your 3D printed dinner doesn’t kill you

New research from the University of Alberta is making 3D printed food safer by utilizing the machine’s own heating element.

The research revealed that the heating component inside a 3D food printer, typically used to keep edible paste pliable for shaping, can also effectively kill Salmonella. This harmful bacteria is responsible for five percent of food-borne illnesses, 24 percent of related hospitalizations, and 16 percent of food-related deaths in Canada annually.

Julia Barsukova, who conducted the research as part of her master’s degree in bioresource technology, emphasized the significance of the findings. “It shows that we can use the printer itself to create safe conditions,” she said. “The heating element is already there, and we know heat kills bacteria, so why not do that while printing food?”

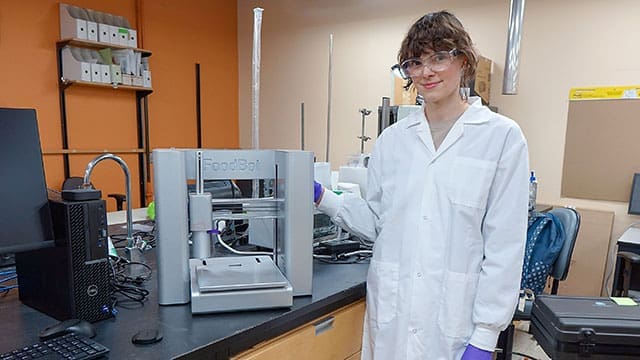

Julia Barsukova’s research is making 3D printed food safer to eat, using the machine’s own heating element. |

| More in Science |

| A deep dive into the meaning of wacky weather terms

|

| Research comes to the rescue to make firefighters’ clothing safer

|

| New study links maternal smoking to childhood obesity risk

|

3D printed foods, including chocolate, sugar, dough, cheese, pudding, mashed potatoes, and vegetable or fruit purées, have seen increased exploration over recent years. 3D printing allows for the creation of foods with intricate shapes, flavours, and textures, catering to everything from home and restaurant meals to personalized diet plans for patients, athletes, and astronauts.

Barsukova, who also holds a bachelor of science in nutrition and food science from the University of Alberta, noted that most scientific research has focused on the appearance of the final product rather than its microbial safety. “There are questions around whether it’s going to form a nice structure, whether it’s going to hold its shape, but the microbial safety aspect of 3D printed foods hasn’t been fully investigated.”

Given that many 3D printed foods require pliability and contain ingredients with high moisture levels, ensuring their microbial safety is crucial. High moisture levels can accelerate bacterial growth if the food is contaminated. “That could be problematic because high moisture levels can speed up bacterial growth if the food is contaminated,” Barsukova said.

3D printed foods, often made as ready-to-eat products, can be contaminated just like any other food. Unlike traditional food manufacturing equipment, 3D printers – mainly marketed to startup businesses and home users – have components that cannot be completely disassembled for thorough cleaning. “If there are microbial pathogens coming from the printer itself or somewhere in the production stage, you can get food poisoning,” Barsukova warned.

Conducted in the U of A’s Food Safety and Sustainability Engineering Research lab, Barsukova’s work pinpointed the optimal times and temperatures for the heating element in the printer, a small stainless steel barrel heated by a thin plastic film. This barrel houses a syringe that dispenses the pliable food paste. During her research, Barsukova contaminated pudding with Salmonella enterica serovar Typhimurium, a pathogen linked to food recalls. She then heated the pudding inside the syringe at various times and temperatures sufficient to kill the bacteria, ranging from 10 to 40 minutes and from 55 C to 66 C.

Results showed that higher temperatures and longer heating times significantly reduced bacterial presence, with the most substantial reduction occurring after 40 minutes at 63 C and 66 C. These findings confirm the effectiveness of the printer’s heating element in killing harmful bacteria.

“This work provides the optimum times and temperatures to kill this particular strain of Salmonella, helping to ensure the printed product is safe to consume,” Barsukova said. Her research also utilized numerical modelling to create heat maps within the syringe, identifying cooler spots where bacteria were not adequately mitigated. Such simulations can be valuable tools for ensuring safety in 3D food printing, she said.

Professor M.S. Roopesh, who co-supervised Barsukova’s research with adjunct professor John Wolodko, highlighted the broader implications of the study. “We were able to see the effect of time-temperature combinations on the microbial safety of a 3D printed product, similar to what occurs during the pasteurization of dairy products or sterilization of canned products,” said Roopesh. His lab is also exploring improvements in the 3D printability of plant proteins using innovative techniques like plasma-activated water bubbles.

Roopesh suggested that this information would be beneficial if 3D food printing reaches industrial-level production of ready-to-eat products. “While the concept needs further research, especially to understand the heat resistance of other microbial pathogens during 3D printing, ways to achieve more efficient, fast heating before and during the printing process could be factors companies target in the future.”

| Staff

The opinions expressed by our columnists and contributors are theirs alone and do not inherently or expressly reflect the views of our publication.

© Troy Media

Troy Media is an editorial content provider to media outlets and its own hosted community news outlets across Canada.